Blast Furnace 5

Furnaces like Blast Furnace 5 were used to produce pig iron by smelting iron ore with lots of other aggregates at temperatures of around 2000°C. A furnace like this could operate continuously for ten years before the internal brickwork had to be relined.

Five blast furnaces were once in use at the Meiderich ironworks but, after the early demolition of two furnaces, just three have been preserved today. Blast Furnace 5 is the only one of these three that is readily accessible for all. Shortly before the closure of the works it was given a complete overhaul and so is in a very good state of preservation.

Today an iron staircase on Blast Furnace 5 leads high up onto a viewing platform, from where you can enjoy a fantastic view of the city of Duisburg, the Ruhr District and the Lower Rhine. But take a careful look and you’ll see more green than you might have expected. The view is particularly beautiful at sunset or at night, when the lights of the city shine out and the park is transformed into a work of art made of light.

Blast Furnace 5 and its viewing platform are open 24/7 but, in the case of snow, ice or stormy weather, the blast furnace is closed for safety reasons.

Blast furnace design

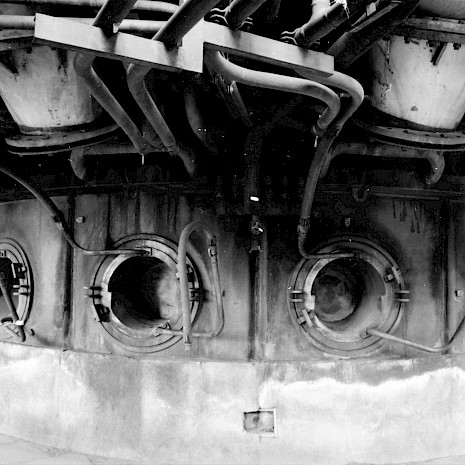

A blast furnace consists of a throat, stack, belly, bosh and hearth. In the throat, the upper area of the blast furnace, the temperature would reach about 200 °C. The further the raw material (ore, coke, sinter, limestone) proceeded down the throat, the hotter it became and expanded. That’s why the blast furnace has a shape widening towards the bottom.

The diameter is widest at the belly and it connects to the bosh where the furnace diameter narrows and the material was able to settle as a heavy molten fluid. In the area below, a hot wind was blown in through the blow moulds. This was the hottest part of the furnace with temperatures of around 2000 °C, creating the molten pig iron and the slag which could now flow into the hearth.

History

The last shift to work on Blast Furnace 5 was on 4th April 1985, 33 years after it was constructed. It was built in 1952 to replace the old Blast Furnace 4 and was subject to a complete overhaul in the ’80s, shortly before it was shut down.

It was not until 1973 that it acquired its present appearance, surrounded by a framework with stages, steps and landings built in. With its modern cooling system and hot blast stoves, it complied with strict environmental protection requirements. However, the EU steel quotas were the reason for its closure. After an eventful industrial history totalling 82 years, the plant and the whole of the Meiderich Ironworks was shut down. Blast Furnace 5 was left behind “shipshape and Bristol fashion” and capable of being blown again. It has been open to the public since 1994, providing access to a viewing platform.